Hello

Welcome

Nice to meet you! I'm a detail-oriented product developer, specializing in the apparel and accessories industries. My meticulous mastery is backed by a 10-year proven track record in product development. I wield an Associate of Arts degree in Fashion Design from Fashion Institute of Design & Merchandising, Los Angeles.

Excels in critical skills for product development, such as:

- Critical software (Microsoft Office, Adobe Illustrator, etc.)

- Quality control for domestic & overseas production

- Technical design

- Tech packs

- Textiles and trim development

- Packaging development

- Conducting fittings

- Product costing

- Calendar creation

FLAT SKETCHES

.jpg/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:370,cg:true)

.jpg/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:370,cg:true)

I created these flat sketch examples with Illustrator and Photoshop. They were created for Kiyonna, a direct-to-consumer women’s plus-size clothing company. Each garment was crafted from knits or stretch wovens at domestic factories. I would receive a hand sketch from the head designer, along with fabric swatches, to produce accurate digital sketches. Facing an incomplete print from a fabric header, I'd use Photoshop to recreate it. I would then use the Photoshop image as a swatch in Illustrator to fill the flat sketch with a correct scale print.

APPAREL DEVELOPMENT

At TravisMathew, I held responsibility for all polo development. I would receive the designer's sketch and graphic files to create tech packs for our overseas vendors. Collaborating with Sourcing department, I would then request lab dips and strike offs for approval. Vendors would quote based on prototype samples, and I would negotiate costs to reach target margin. After style adoption, I would review pre-production and TOP samples for accuracy and quality.

Hardware Development

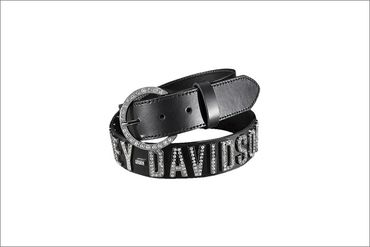

I developed hardware for Harley-Davidson's licensed and private label products. Working with technical drawings from a designer, I would design tech packs that outlined all key measurements, finishes, and trademarks. Our overseas vendors would send rubber mold samples or 3D CADs for my review before proceeding to steel mold. Following this, I would negotiate and track all tooling and sample charges for buckles, metal trims, and ornaments.

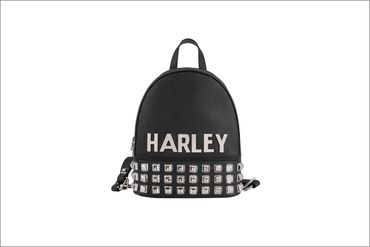

Accessory Development

From large backpacks to small money clips, I have worked on a broad range of bags, belts, and small leather goods. I have sourced leathers from tanneries across the world. In addition, I have developed custom fabrics and trims. Designers would hand off hardware and leather cuttings so that I could coordinate with our in-house sample makers to create a prototype. I would then spec out the proto sample and ship overseas for our vendor to duplicate. Communicating daily with the vendors, I would negotiate costs and track the sample process to ensure all deadlines were met.